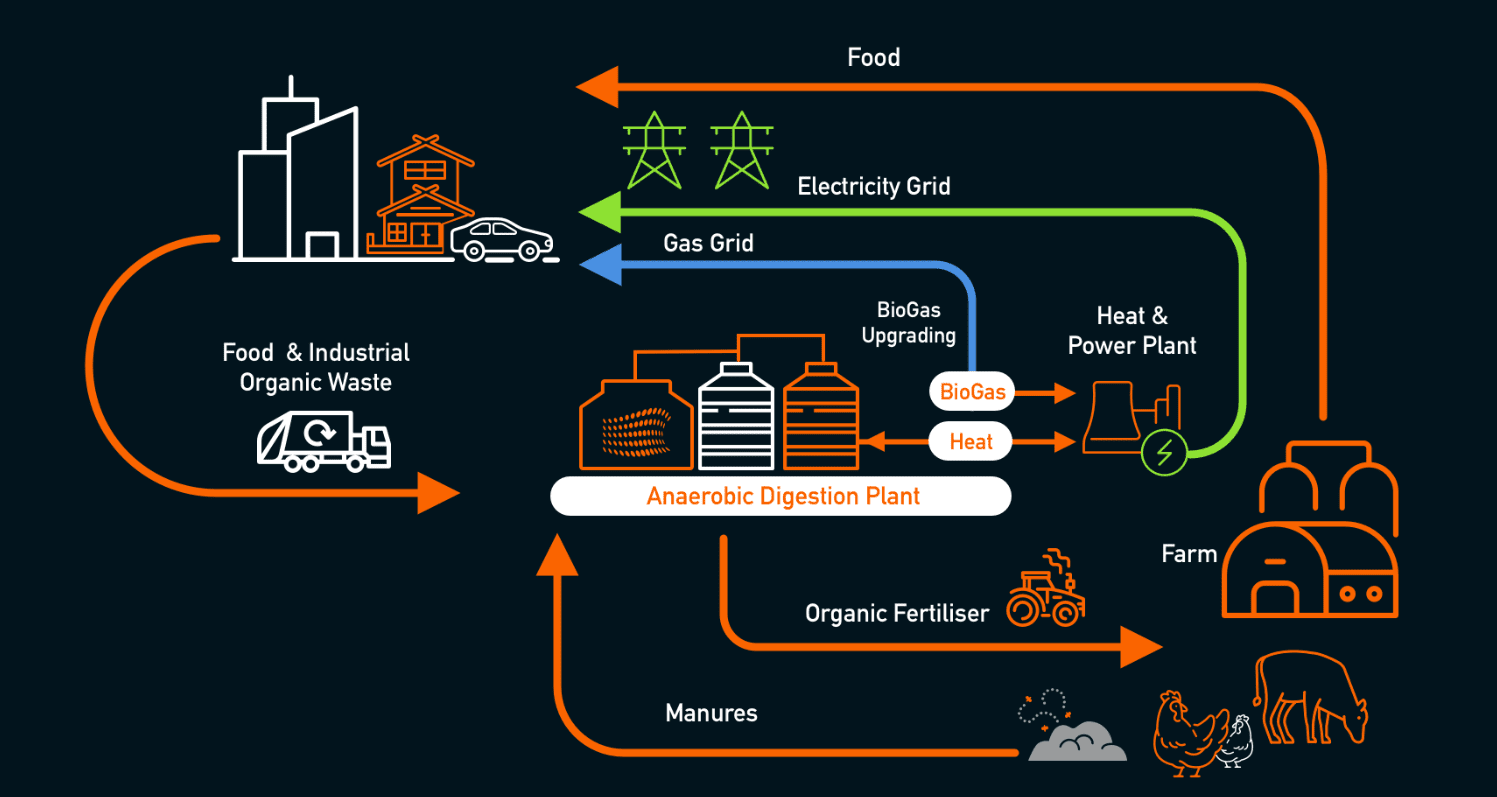

The current talk of the town in vehicular fuel is CBC (Compressed Biogas). Day by day, fossil fuels like petrol, diesel, and LPG are becoming scarce, leading to steep price increases and availability issues. Bio-CNG is a sustainable alternative that can easily replace these fossil fuels. Bio-CNG can be produced from any feedstock; after proper purification, biogas is converted into Bio-CNG/CBG.

This globally accepted fuel has a wide demand across India and is a game-changer for the economy, presenting golden opportunities for green entrepreneurs. We provide comprehensive end-to-end solutions under one roof for all needs, including world-class technology, proven purification processes, high-quality crop-specific organic fertilizers, necessary licensing, and financial support (subsidies, carbon credits) from various organizations.

We have a collaboration with a European company for a multi-feed digester that operates at high solid percentages. One of its advantages is that it requires less water.

We use the following scrubbing systems for biogas purification to Bio CNG or CBG

CBG produced from following sources:

PRESS MUD

Press mud is a residual by-product in the sugar industry that is increasingly recognized as a valuable resource for producing Compressed Biogas (CBG). These by-products provide Indian sugar mills with an opportunity to generate additional income by utilizing them as feedstock for biogas production through anaerobic digestion. Press mud, a waste by-product from sugarcane processing, is particularly well-suited for bio-methanation. The conversion of press mud into biogas also yields high-quality organic fertilizer, beneficial as a soil enricher and nutrient in agriculture.

Farmers associated with sugar factories, as well as other agricultural practitioners and manure dealers, stand to benefit significantly from the steady and reliable supply of organic manure throughout the year from such plants.

NAPIER GRASS

Napier grass is highly suitable as an energy crop for biogas plants due to its ability to thrive on large expanses and ease of harvest. Economically, it proves valuable when conditions for product sale are favorable. This tropical plant can withstand drought and dry conditions, making it resilient. Napier grass (Pennisetum purpureum) is a significant renewable energy source due to its high biomass yield and potential for bio-methane production. It boasts impressive organic compositions: 30.9% total carbohydrates, 27% protein, 14.8% lipids, 18.2% total ash, and 9.1% fiber, making it an ideal feedstock for biogas production.

Different variants of Napier grass yield between 100 to 180 tons per acre annually, offering sustainable livelihoods to farmers through this energy crop

MUNCIPLE SOLID WASTE

Due to urbanization, the increasing urban population has increased the amount of waste generated in urban Indian cities. Out of the overall waste, around 45-55% waste is organic in nature. Out of this organic waste, only about 35-40% waste is suitable for Biogas.

Biggest challenge is the disposal of manure generated through the MSW plants as the raw material is not regulated, the quantity of heavy metals such as Mercury, Arsenic, lead might exceed the allowable parameters. The Biomass such as Paper, Wood, Dried leaves, Wooden shavings are generally high in Lignin and Cellulose and these substances can theoretically suitable for generation of biogas but practically looking at the technology and most importantly the economics is not suitable for the commercial biogas generation.

DAIRY FARMS

India being one of the leading milk generating and processing country has one of the highest milking cattle population. They range from single cattle in a house to a large mechanized dairy farm having thousands of cattle. With these numbers we can use go with cow dung to compressed biogas project not only it we can also convert the waste in to organic fertiliser, it helps to financial independency to the gaushala and dairy farms owners.

POULTRY FARMS

India has now growing poultry farms and there are clusters in some specific parts of the country where we have large concentration of poultry activity. They are located in parts of Telangana, Some parts of Maharashtra, Haryana, Tamil Nadu and Chhattisgarh, Kerala and many more states.

PIGS, HORSE, CAMEL AND OTHER ANIMALS WASTE

In Indian society, piggeries and other animal husbandry is not very common and the economics and technology suitable for processing waste will be similar to cattle farming.

PROCESS WASTE

The process waste is generated through process industries processing organic material. They can be in form of High COD and BOD liquids and or solid organic waste. Also, it can be used for biogas production.